.png?width=1584&height=792&name=Bruce%2030%20years%20(2).png) When you retrofit Rockwell SLC Hardware that has reached it’s end of life, you transform old equipment to perform like new again.

When you retrofit Rockwell SLC Hardware that has reached it’s end of life, you transform old equipment to perform like new again.

We’ve all heard (and probably used) the old saying, “If it ain’t broke, don’t fix it!” While this may work on the farm, it doesn’t cut it in mission-critical applications. EES has recommended on several occasions the replacement of obsolete (and therefore hard to acquire parts for) equipment. This article is about the retrofit of Rockwell SLC hardware that has gone end of life.

What Does End-Of-Life Equipment Mean?

Equipment manufacturers end-of-life equipment regularly as their ability to get chips and other parts dwindles. Once the manufacturer stops making an item, users of that item have to deal with the used (sometimes refurbished) aftermarket. Delivery is a challenge and there is no guarantee that the part will work upon arrival. And the cost is usury.

Which is why its critical to plan out obsolescence through a retrofit project to keep your facility up to date.

Creating a Plan to Update PLC Technology

Three years ago, our team at EES set up a four-year plan to replace the PLC equipment at a major data center in the Northeast. The PC was running Windows XP. The PLCs were various versions of PLC5, SLC500, and MicroLogix. Through careful planning and engineering, the overall system had no downtime and the operators had only minimal manual operation during the changeovers.

EES engineers architected an upgrade path that minimized wiring changes, moved away from obsolete equipment, and improved the overall communication architecture. Starting with an Allied-Telesis 48-port managed switch, the network backbone was overhauled to handle the new traffic. Other network components were upgraded from 10/100MB to 10/100/1000 MB. Hubs and unmanaged switches were replaced by managed switches to assist in managing any down devices.

Designing Out Complexities

Several complexities of the past had to be engineered out of the system. For example, there were custom modules, programmed in “C”, to speak various protocols. While this worked well, it limited the number of people who could support and diagnose it. New ABB/Cylon BACnet routers were installed to speak directly to thermostats and the like without converting to Modbus and then read serially into the PLC. Bi-directional support for setpoints was achieved in this way, as opposed to the old way with two registers, one for read and one for write.

Equipment Retrofits Results

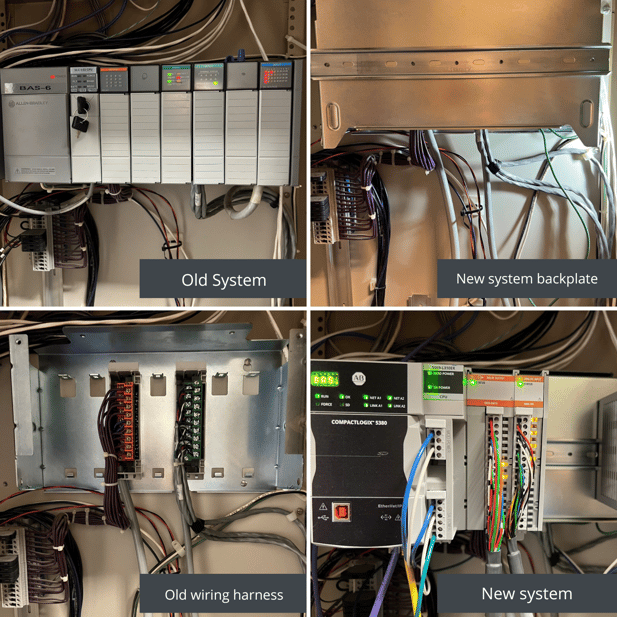

The actual migration, shown below in the following progression of photos, was accomplished in only a few hours. This made it more palatable for the operation staff as they had to monitor the controlled equipment manually during the cutover.

The retired equipment has served as spare parts during the cutover and once the need for the obsolete parts is no longer, the parts will be sold to the aftermarket supplier as a way of helping other customers, lowering landfill usage, and assisting in funding the cutover itself.

Interested in Updating Your Facility?

We want to help you accomplish your manufacturing goals. If you’re interested in learning how EES can help you upgrade your equipment, reach out!